Spot UV, or spot varnish in the packaging industry ruled over decades. However, manufacturers and consumers realized the many benefits of spot UV, or spot varnish, in the packaging industry.

According to the needs of product glazing, local glazing coating is carried out on the prominent parts of

trademarks and packaging printed materials. Compared with the surrounding patterns, the glazing pattern isbright,

bright, and has a strong three-dimensional effect, which can produce unique artistic effects. Therefore, it is

favored by Chinese and foreign merchants.

overview

As an important surface finishing process, UV glazing process has become an important means to realize the value

-added of cartons. The so-called UV varnish refers to coating a layer of UV varnish on the surface of the paper

through a specific glazing equipment, and the surface of the printed product can reach a certain gloss after curing.

Most of the traditional glazing equipment is full-page glazing equipment, that is, it can only glazing the entire

printed product surface, which can protect the printing surface, beautify the carton, and improve the product

grade.

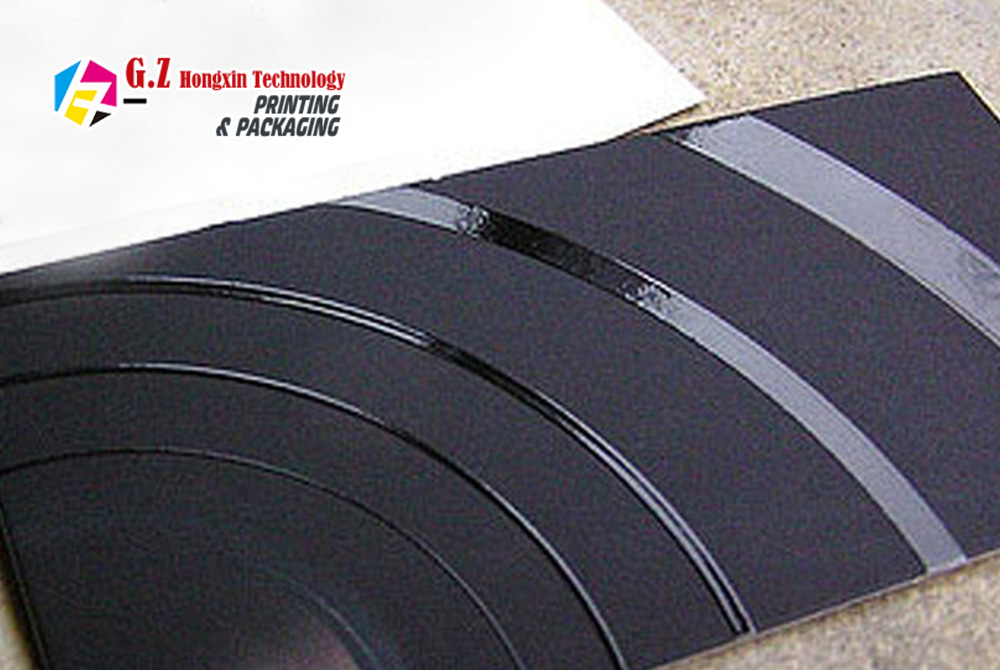

The local UV varnishing process is to varnish some parts or specific patterns of the printed matter, so that these

parts or patterns can have a clear contrast effect with the surrounding graphics, thereby highlighting the focus or

theme of the packaging, reflecting the characteristics of the product, and achieving The purpose of attracting

customers' attention and making purchases. Full-screen UV glazing is more environmentally friendly due to no

solvent volatilization, and it is an alternative to the lamination process; partial UV glazing process highlights the

effect of appealing to product characteristics.

Now, many cosmetics, electrical appliances, food, health care products, etc. have applied partial UV glazing

process on the packaging cartons, which has achieved good publicity and promotional effects.

UV effect

At present, the common partial UV effects are: partial bright light, partial extinction, partial frosting, partial colorful

partial refraction, partial wrinkles and partial ice flowers, etc.

Partial UV can be implemented after lamination, or directly on the printed matter, but in order to highlight the

effect of partial glazing. Generally, it is carried out after the printed matter is coated with a film, and most of them

are covered with a matt film, accounting for about 80% of the local UV coating products. The biggest difference

between partial glazing and full-plate glazing is that one needs to make printing plates and the other is that there

are certain registration requirements for glazing equipment. There are three major elements in local UV glazing,

namely glazing plate, equipment registration and curing equipment. In order to ensure that the local UV glazing

part is consistent with the size of the printed graphic, the photosensitive imaging method should be used when

making the glazing plate.

Classification

1. Partial glazing for screen printing

Screen printing has the characteristics of high ink transfer, thick ink layer and strong three-dimensional effect.

Generally, 200-300-mesh screen should be used for the screen plate for glazing (for glazing effects such as partial

frosting and local colorful, the mesh number is lower), and the tension of the stretching net is 20-25N/cm. Due to

the small investment in equipment. Many books, periodicals and packaging factories prefer screen printing when

increasing local glazing business. Some professional printing and glazing companies improve glazing precision

and production efficiency. Fully automatic roller screen printing machines are already in use. The production speed

can reach 3000 sheets/hour. However, the local glazing of screen printing basically adopts the offline production

mode. On-line rotary screen printing units are rarely used.

2. Partial glazing of flexographic plate

Flexographic printing is characterized by the ability to form thicker coatings with a simpler process.

Therefore, it is quite popular in UV glazing. Flexographic printing local glazing is divided into ordinary flexographic

printing glazing and special flexographic printing glazing, and some simple graphics are still using engraved

rubber letterpress. Flexographic printing local glazing is suitable for off-line glazing and can also realize online

glazing. Using flexographic printing glazing method, combined with anilox roller and cavity scraper, can accurately

control the amount of varnish, and the glazing quality is stable.

3. Partial glazing for gravure printing

Gravure printing also has advantages in local UV glazing due to its thick printing ink layer and high printing

resistance of the gravure cylinder, especially the emergence of sheet-fed gravure printing machines has played a

role in fueling the development of gravure local glazing. However, due to its high plate-making costs, it is mainly

used for long-run glazing business.

4. Other partial glazing methods

Before the emergence of UV varnish, no one would use offset printing for varnish because its printing ink layer is

too thin. Due to the thicker film layer, higher gloss and high overprint accuracy, UV varnish has some applications

in local UV glazing, but it is mainly used for online glazing.

In terms of production methods, local UV glazing machines can also be divided into offline glazing and online

glazing.Off-line glazing refers to printing, and glazing is carried out on special equipment respectively, requiring

the use of special glazing machines or calenders. When off-line varnishing, because the printed matter can be

fully dried, a higher gloss can be obtained than on-line varnishing. In addition, the off-line glazing production has

great flexibility. Equipment investment is small. In-line glazing means that printing and glazing are completed on

one production line, that is, glazing and UV curing devices are added to the printing machine. Allows the print to

be varnished directly after printing.

Partial UV New School Technology

1. Mixed ink technology

Since UV printing or UV glazing is not suitable for application on the surface of highly absorbent printing materials,

and the surface adhesion of printing ink is not good, so most of them need to carry out on-line UV glazing. If all

of them are printed with UV ink, the cost will inevitably increase : If ordinary ink is used for printing, lamination or

full glazing is carried out before glazing, which undoubtedly hinders the application of offset printing on-line

glazing.

The mixed ink technology effectively solves this bottleneck problem. In terms of performance, it combines the

advantages of UV ink and traditional ink, that is, the advantages of photocuring and oxidative polymerization

drying,which improves the synergistic effect of ink surface and UV varnish, and paves the way for online glazing of

offset printing.

2. Reverse glazing

Reverse glazing (Pro-Cure) is relative to traditional local glazing. The traditional glazing method (flexographic

printing, screen printing or gravure printing) is used for partial glazing, and finally partial glazing plate printing

must be used to achieve a high contrast effect of partial graphics. Therefore, the overprint accuracy of glazing and

printing becomes glazing. The key to craftsmanship. The reverse glazing process breaks through the above laws

and solves the registration problem.

3. On-line UV coating

This is the advantage of Hongxin Technology. We have a German manroland 8+1UV in-line coating printing

machine.

In-line coating is not a new technology for flexographic printing and gravure printing, but for offset printing,

which has a wide range of applications, high printing accuracy and high speed, it is launched under the voice of

differentiation and value-added services The glazing technology with innovative ideas. There are four main forms

of online UV glazing methods that have been applied: ordinary ink + double glazing (water-based glazing + UV

glazing); mixed ink + UV glazing; UV ink + UV glazing; UV ink + OP oil + UV glazing (reverse glazing).